Description

Schmalz vacuum clamping technology guarantees efficient production processes on CNC machine tools in the wood, plastics, metal, glass, aeronautical, space, solar and electronics industries. This technology is already used as original equipment on many CNC machines, and the Schmalz Innospann clamping systems can be retrofitted on existing machining centres, permitting decisive improvements in their productivity and operating costs. The possible savings which result from the shorter set-up times are enormous, and the systems pay for themselves very quickly.

Our unbeaten expertise and our wide range of different clamping systems guarantee that we can provide the optimal solution for your individual application.

Our engineers will be happy to advise you personally and, if desired, on your premises. Our service portfolio is rounded off by a comprehensive spare-parts management system for both replacement suction plates and complete suction blocks.

Innovative ideas, many national and international patents, a wide range of systems and closeness to the customer have made Schmalz the world market leader in the area of vacuum clamping technology.

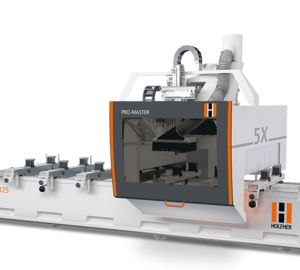

Innospann – for retrofitting machines of all types

The vacuum clamping system Innospann can be retrofitted quickly and easily on any CNC machining center.

The modular design permits extremely individual clamping-technology solutions for the efficient production of one-pass jobs and small batches – regardless of the manufacturer and type of the CNC machining center. The modular system ensures maximum flexibility.

Retrofitting the Schmalz Innospann vacuum clamping system on existing CNC machining centers offers genuine benefits:

- Set-up times reduced by up to 80%

- Low-cost retrofitting solution instead of a major investment in a new machine

- Holding forces up to 50% higher than with conventional clamping systems

- Easy clamping of narrow and curved work pieces

- Retrofitting without modification of the machine

- No need for a template store and time-consuming manufacture of templates

- Flexible positioning of the suction blocks for work pieces of almost all shapes and sizes