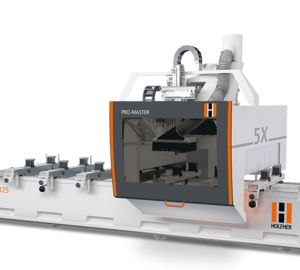

Description

Available Options:

- Vario Table – Automatic console and vacuum pod positioning system in less than 15 seconds- video

Available Table Versions:

- Console table (shown above)*

- Flat table – The solution for complicated workpieces

- Matrix table – Perfect for nested based manufacturing

- META table – Extremly flexible – Elevated pod & nested based manufacturing in one machine – video

Highlights of the Standard XL Machine:

- Strongest standard machine in the market

- Power: 16,0 kW – 21 € HP

- 1,000-24,000 rpm

- Fastest traverse speed in the market

- X axis: 120 m/min. (4,724€ per minute)

- Y axis: 100 m/min

- Z axis: 25 m/min.

- X axis achieves full acceleration at 419mm (16 1/2€)!

- Machine Dimensions:

- X axis vertical drilling: 146.9€/ 12 €€

- Y axis vertical drilling: 55″ all drills

- X axis vertical drilling: 146.9€/ 12 €€

- Y axis vertical drilling: 55″ all drills

- Y axis vertical drilling: 68″ single drill

Complete Machine Features:

- Solid welded machine frame with ground prismatic guide system

- Rack & pinion drive in X & Y axis, ball screw roller spindles in Z-axis

- Workpiece support with 6 hose-less consoles, pneumatically clamped

- 16 Pop-Up Pin Stops (2 per console front/back- 4 Y axis freely positionable)

- 2 large push buttons for clamping and releasing of workpieces2 holders for spare suction cups

- 12 vacuum suction cups (specify 114 X 140 mm/75 x 125 X or Y/ 30 x 125 X or Y)

- 2 measurement tapes for console positioning in X-direction

- 2 measurement tapes for suction cups in Y-direction

- 4-Lifting rails, pneumatically controlled, for positioning workpieces

- 18 vertical boring spindles individually selectable, 6,800 RPM

- 2 double boring spindles for horizontal bores in the X-direction

- 1 double boring spindle for horizontal bores in the Y-direction

- Free space for optional double boring spindle in the X-direction, or for vertical adapter with double force

- 21 HP Router (16.0 Kw) Liquid Cooled 1,000-24,000 RPM HSK-63F

- 12-Position Tool Changer traveling with the head

- Four working fields (right/left/front/back)

- Vacuum pump 100 m€/h with liquid cooling

- Safety Cage as per CE-rules incl. door and safety switch

- Safety tread mat in working area

- Automatic central lubrication for all linear guides in X, Y, and Z-directions

- Transformer for 230V/60

- Cooling Fan for electrical cabinet

- HSK F63 Tool Holders (12 each)

- 1/2 Inch collets for tool holders (12 each)

- Drill Bit Adapters (10 mm) – Left (12 each)

- Drill Bit Adapters (10 mm) – Right (12 each)

- Adapter plate (w/o C-Axis)

- Hand held control unit

- Video conferencing system for video-, audio- and data transfer (AVID)

- Laser Pointer for positioning of the vacuum cups

- Pre-wiring for C-Axis

- Bar code scanner complete with scanner gun, software and interface

Control System:

- PC control panel with 15″ TFT Flat Screen

- 360 degree swivel and tilting adjustment

- Integrated 56k remote maintenance modem

- HOLZ-HER CAMPUS Software

- CD-ROM with CAMPUS Software for the PC in the office

- CAMPUS – Operating area under WINDOWS 2000

- 1 Year On-Site Service Contract with SIEMENS for control systems€