Description

High-efficient panel processing with the latest nesting technology

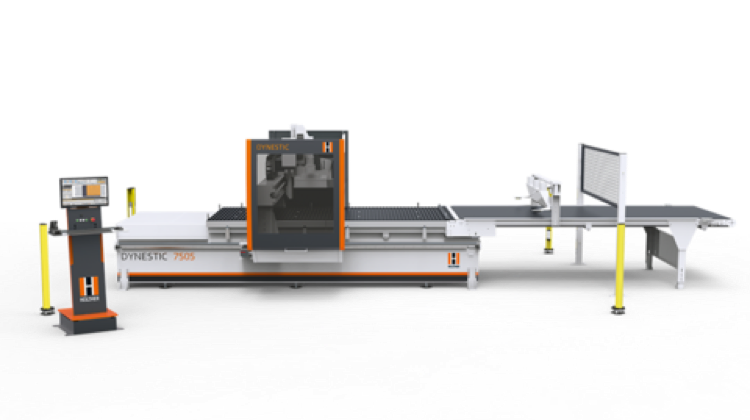

The nesting CNC machine DYNESTIC 7505 enables high efficient panel processing with the newest nesting technology in modern gantry design. With machining dimensions from 3,100 mm (3,700 mm) in X-direction and 1,580 mm in Y-direction, the optimized construction facilitates very short processing cycles with the best processing results in the same time.

The nesting CNC processing center is equipped with an integrated 6-position linear tool changer which could perfectly be extended to 12 tool positions. New highlight is an LED machine lettering which displays the operating status of the machine. Depending on the colour of the lettering it is possible to see which is the current operating status of the DYNESTIC 7505. Moreover the DYNESTIC 7505 has ceramic stored high performance spindles as well as a fully equipped drilling head with up to 24 drilling spindles and grooving saws in X-direction.

The nesting machine DYNESTIC 7505 is available in the classic version and in the push version. The push version contains an automated discharge pusher and an integrated vacuum as well as a discharge table and a conveyor belt.

Here is what the HOLZ-HER DYNESTIC series offers

Here is what the HOLZ-HER DYNESTIC 7507 offers

- Machining in Y Direction: Up to 1580 mm

- Machining in X Direction: up to 3100 / 3700 mm

Technical Details

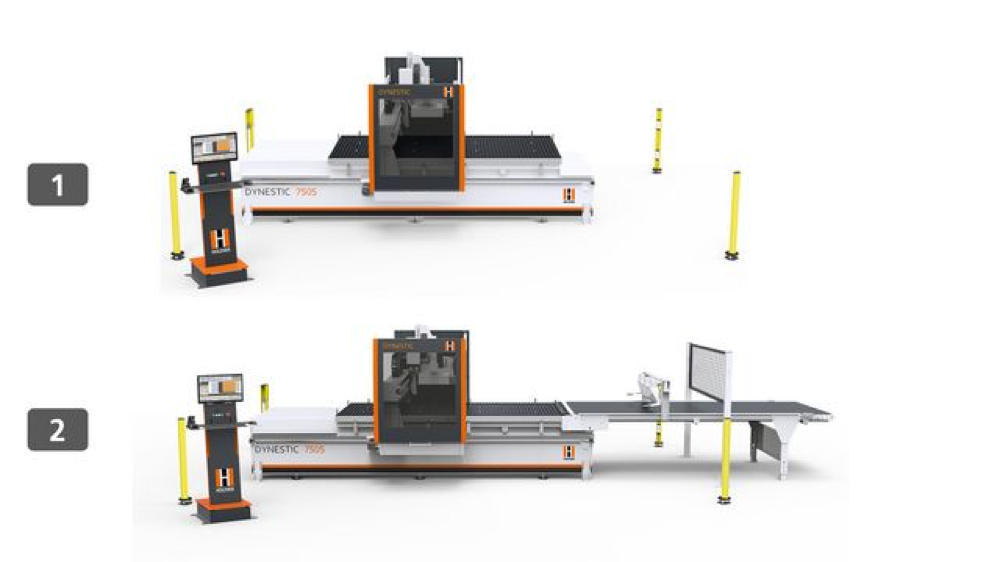

Different equipment versions 7507

Perfectly designed for your application. You can select the individual machine classic by itself or as the push version.

Classic version (1)

- The classic version without automation components.

Push version (2)

- The push version pushes the finished nest on the conveyor belt and cleans the machine table for processing the next panel.

“BetterNest” – the optimum nesting software

Innovative operator software for optimized cutting and processing

The increasing popularity of nesting technology as a combined cutting and CNC processing solution for large quantities of panels has also increased the requirements placed on the nesting software. For this reason, HOLZ-HER offers the “BetterNest” software as an auxiliary module for the CAMPUS / NC Hops software for the functional nesting machining centers in the DYNESTIC series.

This module is available for pure rectangular nesting or as a free-form version with a completely new type of algorithm offering never-before-achievable nesting results with cutting losses far below that obtained with conventional nesting software. In combination with its simple operation in spite of its enormous versatility, it significantly facilitates programming for users in the office and on the machine while ensuring maximum process reliability.

CabinetControl – for programming your furniture simply

Our high quality, user-friendly HOLZ-HER machine control system is an integral part of the machine’s design. The equipment package includes CAMPUS / NC Hops with office and machine license and full-fledged aCADemy CAD software. The integrated CabinetControl Base furniture design software rounds out this premium package. This offer provides the prerequisites for effective machining and convenient operation with barcode interface, manual control unit, import features and much more.

- CabinetControl Base included as standard feature in software package.

- Design of furniture.

- Views can be represented in 2D or 3D.

- Quick adaptation to individual desires of furniture buyers.

- Perfect presentation of furniture.

- Automatic completion of cutting plans.

- Generates CNC machining program automatically at the touch of a button.

- An optional professional version, the CabinetControl PRO, is also available with library, calculation, data transfer to pressure beam saws, etc. Also ideal for planning kitchens and rooms.

CabinetControl Pro – Perfect 3D room planning with cabinet generator

CabinetControl Pro is the extension for professional use in furniture planning and customer presentation. Plan furniture or design entire living situations. Support your customer’s imagination for faster decisions. Present the planned furniture photorealistically from any perspective directly to the customer on site.

Furniture

- Plan your furniture in different room situations: Wardrobes, pitched roof cupboards, dormer cupboards, kitchens, bathroom furniture, office furniture, wardrobes, sliding door cupboards, living room furniture, sideboards, built-in cupboards, hi-fi and TV furniture, counters, beds, tables, etc.

Simple

- As a carpenter, you know how furniture is made. With just a few entries, you can go directly to the finished planning without any CAD knowledge at all. From there it is just a push of a button and all data is ready for production. This way you can quickly and easily get to the planning and work preparation stage.

Planning

- Together with your customer you plan and present your furniture quickly and vividly. You implement any spontaneous change request directly and your customer immediately knows exactly what he is getting. This makes his decision easier and you will get your order more quickly.

The cutting data and the CNC programs for your HOLZ-HER panel saw and the HOLZ-HER CNC machine are automatically generated with the planning. The additional option TrunRAY perfects the display of the created renderings.

Highly flexible nesting table

High-flow nesting table

Nesting technology for rational production. With the nesting process, a porous protective panel – usually a thin MDF panel – is held down on the machine table by a vacuum. It provides a large surface for suction and serves to support the workpieces to be processed. Nesting technology allows optimized processing and cutting of panel materials.

- For formatting nesting cutting plans on the nesting table.

- Workpieces can be processed with manually positioned suction cups.

- The HOLZ-HER nesting table has small matrix dimensions – of only 50 mm – to ensure maximum vacuum flux over the entire table surface.

Integrated drilling head

The DYNESTIC is perfectly equipped with integrated drilling heads.

16 spindles

- Drilling unit with 10 vertical spindles (X = 6 / Y = 4)

- Six horizontal spindles (two double drilling spindles in X direction / one in Y direction)

- Integrated grooving saw in X direction.

- The pressure booster included as a standard feature provides even more power for the drilling unit.

24 spindles

- Drilling unit with 18 vertical spindles (X = 11 + 2 / Y = 6)

- Six horizontal spindles (two double drilling spindles in X direction / one in Y direction)

- Integrated grooving saw in X direction.

- The pressure booster included as a standard feature provides even more power for the drilling unit.

Focused flexibility

- With 14 tool positions the standard linear tool changer is well equipped.

- 1-position X/Y Pick-Up tool changer for transfer of angle gear to spindle in X/Y direction.

- Instead of linear changer an 18-position traveling disk tool changer can be ordered. This is perfect e.g. for 2-field processing in pendulum mode.

TouchTool tool length measurement

TouchTool is the perfect system for the tool length measurement and updates the appropriate values in the tool database. Additionally Touchtool enables an early realization of tool breakage.

TouchProbe workpiece measurement

The precision measuring probe TouchProbe measures workpiece length, workpiece depth and material thickness with its ceramic ball caliper and transmits the data to the control of the CNC machine. Thereby measuring errors in the program are automatically updated.

TouchLabel – overview of labels

TouchLabel – the perfect solution for labeling

The 21,5″ touch screen provides a perfect overview of the nesting results. Simply tap the workpiece and the label printer included in the package prints out a self-adhesive barcode label.

The integrated CAMPUS module label printer allows printout of normal text as well as barcodes (barcode and 2D data matrix). Naturally, your barcode labels can be adapted to your specific requirements with the label template editor.

The perfect solution for your material range

One machine – unlimited possibilities

Due to their flexible options the DYNESTIC models are perfectly designed for the processing of many different materials. The processing of sensitive and heavy materials is enabled because of air buffers. “ColdGun”is suitable for synthetic material, aluminium and composite materials. Due to this “ColdGun” the workpieces and milling tools stay constantly cool. Because of that this option enables extrem long tool lifetimes. Amongst others the following materials can be processed with the DYNESTIC models

- Plexiglass

- Plastics

- Solid surface

- Aluminium composite material

- Alu Core

- Alu Profile

- Panels

- MDF panels

- Solid wood glueboards

Excellent operator ergonomy

The ergonomic design of your workplace is constantly growing in significance. HOLZ-HER offers a control desk, which was developed specifically for the DYNESTIC series. This control desk is equipped with an 21,5″ and 16:9 monitor and ensures perfect operator ergonomics.

Depending on the machine equipment the operator desk can be chosen optionally with a mobile base. The wheels enable to move the desk to the place, where it is most suitable for your working process.

Definitely the full usage

The possibility to strike the workpieces optionally on the front stop bar, makes the DYNESTIC series even more flexible. Formatted workpieces can be positioned and processed easily and precisely. Special vacuums for the grid table allow e.g. horizontal drilling and profile processing on different workpieces.

Efficient vacuum technology

Extremely high performance, efficient vacuum pumps ensure workpiece is held securely. These low maintenance, dry-running pumps are also distinguished by their low noise emissions and extremely low maintenance requirements.

Moreover, our intelligent ECO VAC vacuum control uses a software program to ensure that the required vacuum power is always present when several pumps are used.